Intshayelelo

Iplastiki kunye nokubumba inaliti yerabha kuthatha indawo ebalulekileyo kwishishini lemveliso yanamhlanje. Nokuba ziimveliso zeplastiki eziqhelekileyo kubomi bemihla ngemihla, okanye iimveliso zerabha ezisetyenziswa kakhulu kwindawo yoshishino, itekhnoloji yokubumba inaliti idlala indima ephambili. Eli nqaku lijolise ekungeneni kumahluko phakathi kweplastiki kunye nokubumba inaliti yerabha ukunceda abafundi baqonde ngcono ezi nkqubo zimbini zibalulekileyo zokuvelisa.

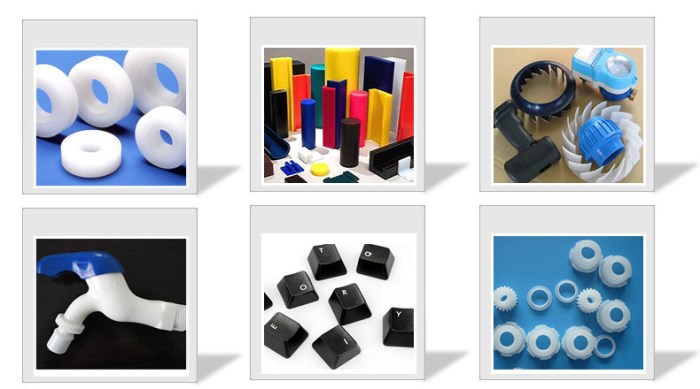

Ukubumba inaliti yeplastiki yinkqubo apho iplastiki etyhidiweyo itofwa ibe ngundo, ethi ipholiswe kwaye iqiniswe ukwenza imveliso ethile yokumila. Ngokwezibalo, inani leemveliso zeplastiki eziveliswa ngokubumba inaliti yeplastiki kwihlabathi likhulu minyaka le. Ngokomzekelo, izinto ezininzi zeplastiki ezisetyenziswa ngabavelisi beemoto, ezifana neendawo zangaphakathi, ii-bumpers, njl., zenziwa ngokubumba inaliti yeplastiki.

Ukubumba inaliti yerabhakukufaka izinto zerabha kwi-mold, emva kwe-vulcanization kunye nezinye iinkqubo, ukwenza iimveliso zerabha ezahlukeneyo. Iimveliso zerabha zikwasetyenziswa ngokubanzi kwiimoto, koomatshini, kwizinto zombane kunye nezinye iindawo. Umzekelo, amavili emoto, amatywina, njl njl., ziimveliso eziqhelekileyo zokubumba inaliti yerabha.

Ukubaluleka kweenkqubo zokubumba iinaliti ezimbini akukhona nje ukuba zikwazi ukuvelisa ngokufanelekileyo iimveliso ezinemilo enzima, kodwa zinokuqinisekisa ukuchaneka kunye nomgangatho weemveliso. Ngokulawula ngokuchanekileyo iiparamitha ezifana nobushushu, uxinzelelo kunye nexesha ngexesha lokutofa, iimveliso ezinomgangatho ophezulu wokuchaneka kunye nomgangatho olungileyo womphezulu unokuveliswa. Kwangaxeshanye, ezi nkqubo zimbini nazo zineengenelo zokusebenza kakuhle kwemveliso kunye neendleko eziphantsi, kwaye zinokuhlangabezana neemfuno zemveliso enkulu.

Isishwankathelo sokubumba inaliti yeplastiki

(1) inkqubo yomgaqo kunye nokuhamba

Umgaqo wenkqubo yokubumba inaliti yeplastiki kukongeza i-granular okanye i-powder yeplastiki ekrwada kwi-hopper yomatshini wokutofa, izinto ezikrwada ziyafudunyezwa kwaye zinyibilike kwindawo equkuqelayo, ziqhutywa sisikrufu okanye ipiston yomatshini wokutofa, ngombhobho kunye nenkqubo yokugalela yokubumba kumgodi wokungunda, kwaye yaphola kwaye yaqiniswa kumgodi wokungunda.

Inkqubo ethile ikakhulu ibandakanya la manyathelo alandelayo: Okokuqala, ukulungiselela izinto ekrwada, ngokweemfuno imveliso ukukhetha izinto zeplastiki efanelekileyo ekrwada, ezifana polystyrene eqhelekileyo, polyethylene, polypropylene njalo njalo. Ezi zixhobo zidla ngokuba neempawu zokusebenza ezahlukeneyo, njengamandla, ukuqina, ukumelana nobushushu, njl. njl., ukuhlangabezana neemfuno zeemveliso ezahlukeneyo. Emva koko izinto eziluhlaza zongezwa kumatshini we-injection wokufudumeza kunye nokunyibilika, kule nkqubo, kuyimfuneko ukulawula ngokuthe ngqo ubushushu bokufudumala, ngokubanzi, izinto ezihlukeneyo zeplastiki zinemigangatho eyahlukeneyo yobushushu obunyibilikayo. Umzekelo, ubushushu obunyibilikayo be-polyethylene buhlala buphakathi kwe-120 ° C -140 ° C, ngelixa ubushushu obunyibilikayo bepolystyrene bumalunga ne-180 ° C -220 ° C.

Xa izinto ezikrwada zinyibilika kwaye zihamba, zityhalwa ngesikrufu okanye ipiston yomatshini wokutofa kumgodi wokungunda ngombhobho kunye nenkqubo yokugalela yokubumba. Kule nkqubo, uxinzelelo lwe-injection yiparameter ephambili, efuna ukuba ibe nkulu ngokwaneleyo ukoyisa ukuchasana kokunyibilika ngexesha lokuhamba kunye nokuqinisekisa ukuba ukunyibilika kunokugcwalisa i-mold cavity. Ngokubanzi, uxinzelelo lwenaliti lunokuba phakathi kwamashumi ukuya kumakhulu empa.

Ekugqibeleni, kwinqanaba lokupholisa, iplastiki ipholile kwaye iqiniswe kwi-mold cavity ngokusebenzisa inkqubo yokupholisa ye-mold. Ubude bexesha lokupholisa buxhomekeke kuhlobo lweplastiki, ubukhulu bemveliso kunye nezinye izinto. Ngokuqhelekileyo, ixesha lokupholisa leemveliso ezibhityileyo lifutshane, elinokuba phakathi kwamashumi emizuzwana kunye nemizuzu embalwa; Ixesha lokupholisa leemveliso ezityebileyo liya kwandiswa ngokufanelekileyo.

(2) Iimpawu kunye neenzuzo

Ukubumba inaliti yeplastiki ineempawu ezininzi kunye neenzuzo. Okokuqala, inokwenza iimilo ezintsonkothileyo. Ngenxa yokuba iplastiki inobumanzi obulungileyo kwimeko enyibilikileyo, inokuzaliswa yimiqolo entsonkothileyo yokungunda, ukuze ivelise iimveliso zeplastiki ezineemilo ezahlukeneyo ezintsonkothileyo, ezinjengeemveliso ezinemingxuma yangaphakathi kunye nezakhiwo ezibuyela umva.

Okwesibini, ukuchaneka kuphezulu. Ngokulawula ngokuchanekileyo iiparamitha ezinje ngeqondo lobushushu, uxinzelelo kunye nexesha ngexesha lenkqubo yokutofa, iimveliso ezinomgangatho ophezulu wokuchaneka zinokuveliswa, kwaye ukunyamezelwa komda kunokulawulwa phakathi kweengcingo ezimbalwa ukuya kwezininzi. Umzekelo, amanye amaqokobhe emveliso ye-elektroniki achanekileyo anokufikelela kwiimfuno ezichanekileyo zomgangatho ophezulu ngokubumba inaliti yeplastiki.

Ukongeza, iimboli zeplastiki zenaliti ziyahlukahlukana, zifanelekile kwiindlela ezahlukeneyo zokurhweba. Iintlobo zokubumba zesitofu ezahlukeneyo zinokuyilwa kwiimveliso ezahlukeneyo ngokwemilo yazo, ubungakanani kunye neemfuno zokusebenza. Ngaphezu koko, ukubunjwa kwenaliti kunokuveliswa ngobuninzi, kunye nokusebenza kakuhle kwemveliso, kwaye kufanelekile kwiindlela ezahlukeneyo zokurhweba, njenge-OEM (umvelisi wesixhobo sokuqala) kunye ne-ODM (umvelisi woyilo wokuqala).

Ngelo xesha, ukubumba inaliti yeplastiki kunoluhlu olubanzi lokuziqhelanisa. Ingasetyenziselwa ukuvelisa iimveliso zeplastiki ezahlukeneyo, ukusuka kwiimfuno zemihla ngemihla ezifana ne-tableware, iithoyi, ukuya kwiimveliso zemizi-mveliso ezifana neendawo ezivaliweyo zombane, iindawo zemoto njalo njalo. Ngokwezibalo, malunga ne-70% yeemveliso zeplastiki zehlabathi ziveliswa ngokubumba inaliti.

Isishwankathelo somatshini wokubumba inaliti yerabha

(1) inkqubo yomgaqo kunye nokuhamba

Umatshini wokubumba inaliti yerabhaluhlobo lwetekhnoloji yokucubungula ethumela izinto kwi-mold yokubumba nge-extruder yerabha ephezulu yokusebenza, kwaye emva koxinzelelo oluthile kunye nobushushu, izinto eziluhlaza zerabha zenza imilo efunekayo kunye nobukhulu ekubunjeni.

Inkqubo ethile imi ngolu hlobo lulandelayo:

Umsebenzi wokulungiselela: kubandakanywa ukuhlolwa kwerubha ekrwada, ukomisa, ukufudumeza kwangaphambili kunye neminye imisebenzi, kunye noyilo lokungunda, ukuvelisa kunye nokulungiswa kweempazamo. Ukuhlolwa kwemathiriyeli yerabha ekrwada kubalulekile ukuqinisekisa ukuba umgangatho kunye nokusebenza kwemathiriyeli ekrwada kuyahlangabezana neemfuno zeemveliso. Umzekelo, kwezinye iimveliso zerabha ezisebenza kakhulu, ezinje ngamavili emoto, izitywina, njl.njl., kuyafuneka ukuba ukhethe izixhobo ezikumgangatho ophezulu zerabha ukuqinisekisa ukomelela, ukumelana nokunxiba kunye nokumelana nokuguga kweemveliso. Kwinkqubo yokomisa kunye nokufudumala, ubushushu kunye nexesha kufuneka balawulwe ngokungqongqo ukuphepha ukomisa ngokugqithiseleyo okanye ukufudumeza okwaneleyo kwezinto eziluhlaza zerabha. Uyilo kunye nokuveliswa kwesikhunta kufuneka kuqulunqwe ngononophelo ngokwemilo, ubungakanani kunye neemfuno zokusebenza kwemveliso ukuqinisekisa ukuchaneka kunye nomgangatho wokubumba.

Ukuveliswa kwezinto eziphathekayo: Iinqununu zerubha ezomileyo zongezwa kwi-rubber extruder, kwaye izinto eziphathekayo ziphathwa kwangaphambili ngoluhlu lweenkqubo ezifana nokufudumala kunye nokukhupha. Kule nkqubo, ukusebenza kunye neparameter Izicwangciso ze-rubber extruder zibaluleke kakhulu. Ngokomzekelo, ubushushu be-extruder, isantya se-screw kunye nezinye iiparitha ziya kuchaphazela ngokuthe ngqo umphumo weplastiki kunye nomgangatho wezinto zerabha. Ngokuqhelekileyo, ubushushu be-extruder bunokuba phakathi kwe-100 ° C kunye ne-150 ° C, kwaye isantya se-screw sinokuba phakathi kwamashumi ukuya kumakhulu eenguqu ngomzuzu, kwaye iiparamitha ezithile kufuneka zilungelelaniswe ngokohlobo kunye neemfuno zokusebenza kwezinto zerabha.

Ukubumba: Izinto zerabha eziphathwe kwangaphambili zondliwa kwi-mold ngumatshini wokutofa kwinkqubo yokubumba. Ngeli xesha, uxinzelelo oluthile kunye nokushisa kufuneka kudibaniswe ukwenza irabha ekrwada yenze imveliso yesimo esifunwayo kunye nobukhulu. Uxinzelelo kunye nobushushu kwinkqubo yokubumba yiparameters eziphambili, uxinzelelo lunokuthi lube phakathi kwamashumi ukuya kumakhulu e-mpa, kwaye ubushushu bunokuba phakathi kwe-150 ° C kunye ne-200 ° C. Iimveliso zerabha ezahlukeneyo zineemfuno ezahlukeneyo zoxinzelelo kunye nobushushu, umzekelo, kwezinye iimveliso zerabha ezinkulu, ezifana nezikrini zegubu lerabha, i-browser shock absorbers, njl.

Ukunyanzeliswa koxinzelelo: Emva kokuba ukubunjwa kugqityiwe, kuyimfuneko ukupholisa phantsi kunye nokudiliza ukususa iimveliso zerabha kwi-mold. Inkqubo yokupholisa kufuneka iqhutywe ngokucothayo ukuphepha ukuguqulwa okanye ukuqhekeka kweemveliso ngenxa yokutshintsha kweqondo lokushisa ngokukhawuleza. Lumka xa udiliza ukuthintela ukonakalisa imveliso.

(2) Iimpawu kunye neenzuzo

Umthamo omnye wokuvelisa: umthamo omnye wokuvelisa umatshini wokubumba inaliti yerabha ngokuqhelekileyo uphakathi kwamashumi eegram kunye neekhilogram ezininzi, nto leyo ephucula kakhulu imveliso yeemveliso ezigqityiweyo.

Ukuchaneka kwemveliso ephezulu: Umatshini wokubumba umjovo werabha unokulawula ngokuchanekileyo ubushushu, uxinzelelo kunye nezinye iiparitha zezinto ngexesha lokubumba, ngaloo ndlela uphucula kakhulu ukuchaneka kwemveliso.

Umjikelo omfutshane wokubumba: Kuba ukubumba inaliti yerabha kunokwenza iimveliso ezininzi ngaxeshanye, kwaye umthamo wemveliso mkhulu, umjikelo wokubumba umfutshane. Umzekelo, kwimveliso yamalungu athile emoto, ukusetyenziswa kwenkqubo yokubumba inaliti yerabha kunokuphucula kakhulu ukusebenza kakuhle kwemveliso kunye nokunciphisa umjikelo wemveliso.

Umgangatho ophezulu wemveliso egqityiweyo: ukubunjwa kwenaliti yerabha kunokunciphisa imveliso ngenxa yokubumba okungalinganiyo, amaqamza kunye nezinye iingxaki, ukwenzela ukuba umgangatho wemveliso uphuculwe kakhulu. Umzekelo, izitywina zeemoto eziveliswe yinkqubo yokubumba inaliti yerabha zinokutywinwa kakuhle kunye nokunganyangeki, okunokuphucula ngokufanelekileyo ukusebenza kunye nobomi benkonzo yeemoto.

Umahluko phakathi kweplastiki kunye nokubumba inaliti yerabha

(1) Umahluko kwiimpawu zezinto eziphathekayo

Izinto eziluhlaza zeplastiki zihlala zi-thermoplastic okanye i-thermosetting resin, enobunzima obuphezulu kunye nokuqina, kunye nezixhobo ezahlukeneyo zeplastiki zineempawu ezahlukeneyo zokusebenza, njengamandla, ukuqina, ukuxhathisa ukushisa kunye nokunye. Ngokomzekelo, i-polyethylene inokumelana kakuhle neekhemikhali kunye nokufakelwa kombane, kodwa amandla ayo kunye nokuxhathisa ukushisa kuphantsi; I-Polystyrene inokucaca okuphezulu kunye nobunzima, kodwa i-brittle. Ezi mpawu zigqiba ukuba iplastiki idinga ubushushu obuthile kunye noluhlu loxinzelelo ngexesha lokubunjwa kwenaliti ukuze kuqinisekiswe ukuba izinto ezikrwada zinokunyibilika ngokupheleleyo kwaye zigcwalise umngxuma wokungunda.

Izinto eziluhlaza zerabha yirubha yendalo okanye irabha yokwenziwa, ene-elasticity ephezulu kunye nokuguquguquka. Irabha idla ngokuthambileyo kwaye kulula ukuyikhubaza kwimeko engavulwanga, ngelixa inamandla aphezulu kunye nokunganyangeki emva kokutshatyalaliswa. Iimpawu ze-elastic zerubha zenza kube yimfuneko ukuba kuthathelwe ingqalelo izinga lokuncipha kunye nokuqina kwezinto eziphathekayo kwinkqubo yokubumba i-injection ukuqinisekisa ukuchaneka kobukhulu kunye nokuzinza kobume bemveliso. Ngokomzekelo, xa uyila i-mold yeemveliso zerabha, kuyimfuneko ukuthathela ingqalelo ukuba izinga lokuncipha kwerabha likhulu, ngokuqhelekileyo liphakathi kwe-1% -5%, ngelixa izinga lokunciphisa iplastiki liphakathi kwe-0.5% kunye ne-2%.

(2) Umahluko kwiiparamitha zenkqubo

Ngokubhekiselele kwiqondo lobushushu, iqondo lobushushu lokubumba inaliti yeplastiki lihlala liphezulu, kwaye izixhobo ezahlukeneyo zeplastiki zinemigangatho eyahlukeneyo yobushushu bokunyibilika. Ngokomzekelo, ukushisa okunyibilikayo kwe-polyethylene ngokuqhelekileyo kuphakathi kwe-120 ° C kunye ne-140 ° C, kwaye iqondo lokushisa elinyibilikayo le-polystyrene li malunga ne-180 ° C kunye ne-220 ° C. Iqondo lokushisa lokubumba inaliti yerabha liphantsi, ngokubanzi phakathi kwe-100 ° C kunye ne-200 ° C, kwaye iqondo lokushisa elithile lixhomekeke kuhlobo lwerabha kunye nentsebenzo. Umzekelo, ubushushu be-vulcanization yerabha yendalo buhlala buphakathi kwe-140 ° C kunye ne-160 ° C, kwaye ubushushu be-vulcanization yerabha yokwenziwa bunokwahluka.

Ngokubhekiselele kuxinzelelo, ukubumba inaliti yeplastiki kufuna uxinzelelo oluphezulu lwenaliti, ngokubanzi phakathi kwamashumi ukuya kumakhulu e-mpa, ukoyisa ukuchasana kokunyibilika kwinkqubo yokuhamba kunye nokuqinisekisa ukuba inyibilika inokuzalisa umgodi wokungunda. Uxinzelelo lokubumba inaliti yerabha lusezantsi kakhulu, ngokubanzi phakathi kwamashumi ukuya kumakhulu empa, kodwa kwezinye iimveliso zerabha ezinkulu, uxinzelelo oluphezulu lunokufuneka. Umzekelo, xa uvelisa iimveliso zerabha ezinkulu ezifana nezikrini zerubha zerubha kunye ne-browser shock absorbers, uxinzelelo oluphezulu luyafuneka ukuze kuqinisekiswe umgangatho wokubumba weemveliso.

(3) Umahluko kwiimpawu zemveliso

Ngokumalunga nokubunjwa, ukubumba inaliti yeplastiki kunokuvelisa iindidi zeemveliso ezinemilo entsonkothileyo, njengeemveliso zeplastiki ezinemingxuma yangaphakathi, izakhiwo ezibuyela umva, njl.

Ngokuchaneka, ukubumba inaliti yeplastiki kunokuvelisa iimveliso ezinokuchaneka komgangatho ophezulu, kwaye ukunyamezela komgangatho kunokulawulwa phakathi kweengcingo ezimbalwa kunye neengcingo ezininzi. Ukuchaneka kweemveliso zokubumba inaliti yerabha kusezantsi kakhulu, kodwa kwezinye iimveliso zerabha ezisebenza kakhulu, ezinje ngetywina lemoto, njl.njl., inokufezekisa iimfuno zokuchaneka okuphezulu.

Ngokuphathelele ukusetyenziswa, iimveliso zeplastiki zisetyenziswa ngokubanzi kwiimfuno zemihla ngemihla, iimveliso zoshishino kunye nezinye iindawo, ezifana ne-tableware, iithoyi, iqokobhe lombane, iinxalenye zemoto njalo njalo. Iimveliso zerabha zisetyenziswa ikakhulu kwimoto, koomatshini, kwi-electronics kunye namanye amabala, njengamatayara, itywina, izinto zokuthambisa ezothusayo njalo njalo.

Ukuqukumbela

Kukho umahluko ocacileyo phakathi kweplastiki kunye nokubumba inaliti yerabha kwiimpawu zemathiriyeli ekrwada, iiparamitha zenkqubo kunye neempawu zemveliso.

Ngokombono weempawu zezinto ezibonakalayo, izinto zeplastiki eziluhlaza zihlala zi-thermoplastic okanye i-thermosetting resins, ezinobunzima obuphezulu kunye nokuqina, kunye neeplastiki ezahlukeneyo zineepropati ezahlukeneyo. Izinto eziluhlaza zerabha yirubha yendalo okanye irabha yokwenziwa, ene-elasticity ephezulu kunye nokuguquguquka.

Ngokumalunga neeparamitha zenkqubo, iqondo lobushushu lokubumba inaliti yeplastiki liphezulu, iqondo lobushushu lokunyibilika leeplastiki ezahlukeneyo lahlukile, kwaye uxinzelelo lwenaliti luphezulu ukuqinisekisa ukuba ukunyibilika kugcwele umngxuma wokungunda. Iqondo lobushushu lokubumba inaliti yerabha lisezantsi kakhulu, uxinzelelo nalo luphantsi, kodwa iimveliso zerabha ezinkulu zinokufuna uxinzelelo oluphezulu.

Iimpawu zeMveliso, ukubumba inaliti yeplastiki kunokuvelisa iimveliso zemilo entsonkothileyo, ukuchaneka okuphezulu, okusetyenziswa ngokubanzi kubomi bemihla ngemihla kunye nakwimimandla yemizi-mveliso. Ngenxa yokunwebeka okuphezulu, iimveliso zerabha zihlala zilula ngokwemilo kwaye zisezantsi ngokuchaneka, kodwa iimveliso zerabha ezisebenza kakhulu zinokuhlangabezana neemfuno ezichanekileyo, ezisetyenziswa ikakhulu kwiimoto, oomatshini, i-elektroniki kunye namanye amacandelo.

Ezi nkqubo zimbini zokubumba iinaliti zibalulekile kumashishini anxulumeneyo. Kushishino lweemveliso zeplastiki, ukubumba inaliti yeplastiki kusebenza kakuhle, ixabiso eliphantsi, linokwanelisa iimfuno zemveliso emikhulu, kwaye libonelela ngeendidi ngeendidi zeemveliso kwiinkalo ezahlukeneyo. Kushishino lweemveliso zerabha, umthamo omnye wemveliso yokubumba inaliti yerabha inkulu, ukuchaneka kwemveliso kuphezulu, umjikelo wokubumba umfutshane, kwaye imveliso egqityiweyo ikumgangatho ophezulu, obonelela ngamacandelo aphambili kunye netywina kunye nezinye iimveliso zemoto, oomatshini kunye namanye amashishini, eqinisekisa uphuhliso oluzinzileyo lwala mashishini. Ngamafutshane, iplastiki kunye nokubumba inaliti yerabha kudlala indima engenakuthathelwa indawo kwimveliso yanamhlanje, kwaye iimpawu zabo kunye neenzuzo zabo zibonelela ngenkxaso eqinileyo kuphuhliso lwamashishini ahlukeneyo.

Ixesha lokuposa: Nov-08-2024