- Uvavanyo lwe-Tensile:Uvavanyo lwe-tensile lumisela ukomelela, ukomelela, kunye nemodyuli yokunwebeka kwemathiriyeli yerabha.

- Uvavanyo loxinzelelo:Uvavanyo loxinzelelo lulinganisa indlela izinto eziziphatha ngayo phantsi kwemithwalo etyumzayo kunye nokubuyiselwa kwayo.

- Uvavanyo lokuqina:Uvavanyo loBulukhuni lulinganisa ukuxhathisa kwemathiriyeli ekungeneni.

- Uvavanyo lokuguga:Uvavanyo lokuguga lulinganisa ukonakaliswa kwexesha elide kokusingqongileyo.

- UVavanyo loKuxhathisa kweenyembezi:UVavanyo loKuxhathisa iinyembezi luvavanya ukuba isixhobo simelana kangakanani na nokukhula kweziqhulo okanye ukusikwa.

- UVavanyo loKuxhathisa kwiMichiza:UVavanyo lokumelana neeKhemikhali luvavanya ukusebenza ngokuchasene neoyile, amafutha, kunye nezinyibilikisi.

- Uvavanyo lweseti yoxinzelelo:Uvavanyo lweseti yoxinzelelo lutyhila amandla esixhobo sokuphinda abuyele emva kotshintsho oluzinzileyo.

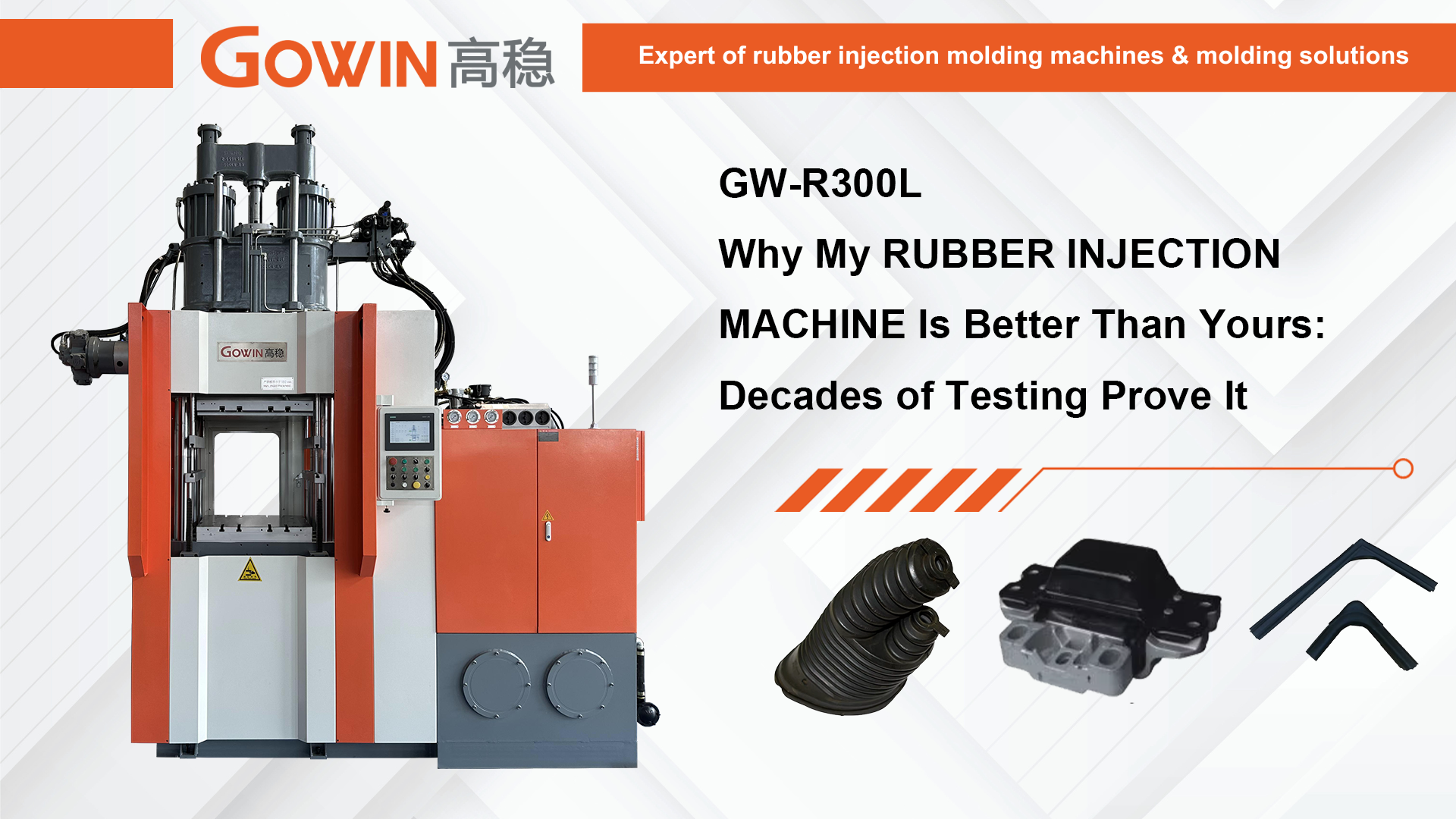

- Ukubumba irabha kunye noVavanyo lweMathiriyeli yeRubha:Ezi ayizobhokisi nje zokukhangela; zisisiseko sezinto ezinokuqikelelwa, ezinomgangatho ophezulu wokusebenza. Kwaye emva kweminyaka engama-30+ kuyila amabali entliziyo yomjikelo weendaba wokwenziwa kwerabha, ndingakuxelela ngokungathandabuzekiyo oku: umlinganiselo wokwenyani womatshini wokubumba inaliti yerabha ayilophepha lawo leenkcazo, kodwa indlela olwenza ngayo ngaphakathi olu mvavanyo ngemibala ephaphazelayo, ngokungaguqukiyo, imini nemini. Eyam yenza. Makhe ndikuchazele ukuba kutheni eyakho inokuba sisilela.

Ngaphaya kwePlaten: Apho uvavanyo ludibana nokusebenza komatshini

Abavelisi abaninzi bagxila kuphela kumaxesha okujikeleza kunye neetoni. Amaxesha omjikelo akathethi nto ukuba amalungu akho ayasilela kwiimvavanyo zeseti yoxinzelelo emva kweenyanga ezintandathu kwi-injini bay. I-Tonnage ayibalulekanga ukuba uxinzelelo lomgodi olungahambelani lukhokelela ekufundweni kobunzima obuguquguqukayo kwimveliso enye. Oomatshini bam benziwe ngokuqonda okubalulekileyo ukuba yonke inkalo yokusebenza kwabo ichaphazela ngokuthe ngqo ezo ziphumo zovavanyo zibalulekileyo ezantsi komsinga.

1. Ukuchaneka okuchaza i-Tensile & Elongation: Ukufezekisa i-molecular structure efunekayo kumandla aphezulu kunye nokwandisa iqala ngokuchaneka okungahambelaniyo ekulawuleni ubushushu kunye nesantya senaliti. Ukwahluka okuncinci kwiqondo lobushushu lokunyibilika kuchaphazela kakhulu ukuxinana kwe-cross-linking - eyona nto iphambili kwiipropathi zokunyibilika. Ukuqhuba kwam ngokuthe ngqo, inkqubo yokutofa kwe-servo evaliweyo ayifuni nje ukuchaneka; inika ukunyibilika kokudubula emva kokudutyulwa, iqinisekisa ukuba izinto ezingena kumngundo zinembali yobushushu efunekayo ukubetha ezo nkcukacha zokuqina. Oomatshini abakhuphisanayo abaxhomekeke kwiihydraulics ezindala abanakukwazi ukungqamanisa nozinzo lwe-thermal, ekhokelela kutshintsho lwebhetshi-to-batch olubulala ukungaguquguquki kovavanyo lwakho lwe-tensile- kunye nodumo lwakho ngabavelisi bokubumba irabha ababonelela ngenaliti ebalulekileyo yokubumba amacandelo eemoto.

2. I-Compression & Compression Set eyimfuneko: Cinga umatshini wokubumba irabha woxinzelelo ngumdlalo kuphela kwezi mpawu? Cinga kwakhona. Oomatshini bokubumba inaliti yerabha yanamhlanje echaneke kakhulu, njengam, bafikelela kwiipropathi zokucinezela ezikhuphisana nokubunjwa koxinzelelo lwemveli, kodwa ngobuchule obuphezulu kakhulu kunye nobuchule bejometri entsonkothileyo. Imfihlelo? Ulawulo olungapheliyo kumandla obambezele kunye neeprofayili zoxinzelelo lwenaliti. I-clamp force engahambelani ikhokelela kwi-flash, eguqula i-geometry yoxinzelelo olusebenzayo lwenxalenye ngexesha lovavanyo. Ukulawulwa kakubi koxinzelelo ngexesha lokutofa kunye nezigaba zokunyanga kudala uxinzelelo lwangaphakathi kunye ne-vulcanization engaphelelanga - ezona zizathu ziphambili emva kokungaphumeleli koxinzelelo oluyintlekele. Ixesha lokwenyani lomatshini wam, ulawulo loxinzelelo oluguquguqukayo kunye neeplatens ezikhokelayo kwishishini ziqinisekisa ukuhanjiswa koxinzelelo lomgodi ofanayo. Oku kuguqulela ngokuthe ngqo kwiindawo ezicinezela ngokuqikelelwayo kwaye ziphinde zibuyele njengoko kuchaziwe, ibhetshi emva kwebhetshi, ibalulekile ekutywineni kwimakethi ekhulayo yezixhobo zerabha ezibunjiweyo zeemoto.

3. Ukuqina: AyikoKuqulunqwa nje: Ucacisa imathiriyeli ye-70 Shore A. Kutheni le nto iinxalenye zihluka ukusuka ku-68 ukuya kuma-72 ukunqumla ukungunda, okanye okubi ngakumbi, ukudutyulwa ukuya kutsho? Ukusasazwa okungahambelaniyo kwezizalisi, ukuvuthuluka okungalinganiyo ngenxa yemithamo yobushushu ngaphakathi kumngxunya, okanye iipokotho zomoya ezibanjiweyo zihlala zizityholo ezifihlakeleyo ezenziwa ngumatshini. Umtshini wam ulwa noku:

I-Ultra-Precise Temperature Zones: Ukulawulwa ngokuzimeleyo, kunye ne-overshoot encinci / i-undershoot, iqinisekisa ukuhanjiswa kobushushu obufanayo kuyo yonke indawo yokubumba.

Uyilo oluPhezulu lweScrew kunye nokuxuba: Yenzelwe iplastikhi ehlanganisiweyo edibeneyo kunye nokusasazwa kwesihluzi ngaphambi kokutofa, ukuphelisa iindawo ezithambileyo.

I-Vacuum Molding Capability (Ukhetho kodwa lubalulekile): Umgangatho kwimifuziselo yam emininzi, isusa ngokusebenzayo umoya kunye nee-volatiles kwi-cavity, ukukhusela i-voids kunye neziphene ezingaphezulu ezenza ukufundwa kobunzima. Ngaba umatshini wakho wokubumba inaliti yerabha esemgangathweni ye-silicone ingabanga inqanaba elifanayo lolawulo kwezi zinto?

4. Ukoyisa ukuguga, ukukrazula, kunye nokuchasana neekhemikhali: Umdlalo omde: Olu vavanyo luveza ubuthathaka obakhelwe kwinxalenye ngexesha lokubumba. Inganyangeki ngenxa yolawulo lobushushu obungazinzanga? Lindela ukunganyangeki kokuguga kunye nokuxhathisa imichiza. I-voids yangaphakathi okanye ugxininiso loxinzelelo olusuka kwisiphithiphithi? Kiss ukumelana neenyembezi ndlela-ntle. Ukutya ngokugqithisileyo kumaqondo obushushu agqithisileyo okanye ukubamba amaxesha? Ubuqhophololo buqalisa, ukungaphumeleli kwiimvavanyo ezininzi. Ulawulo oluvaliweyo lomatshini wam phezu kwayo yonke iparamitha yobushushu (umgqomo, umlomo, imbaleki eshushu, iplaten) kunye neprofayile yokutofa (isantya, uxinzelelo, indawo) iqinisekisa ngokuthe ngqo ubungakanani bamandla obuziswe kanye ngexesha elifanelekileyo. Le vulcanization echanekileyo ayinakuxoxiswana kwiindawo ezilungiselelwe iindawo ezibuhlungu - cinga iimveliso zokubumba i-rubber yocingo kwiipakethi zebhetri ze-EV okanye itywina kwi-chemical processing. Ngumahluko phakathi kwendawo ehamba ngeeyure ezingama-1000 zokuguga kobushushu kunye nenye eqhekeka kwi-500.

5. Yakhelwe ukuSila: Ukuthembeka yiParameter yoVavanyo kakhulu: Owona matshini uhambelanayo awunaxabiso ukuba uphantsi ukulungiswa rhoqo ngeveki. Ixesha lokuphumla libulala inzuzo kwaye inyanzelisa imveliso ekhawulezileyo, ibeka esichengeni umgangatho kunye neziphumo zovavanyo. Iminyaka engamashumi amathathu kule ntsimi indifundise apho iikona zisikwa khona. Oomatshini bam basebenzisa iprimiyamu, izinto ezifunyenwe kwihlabathi liphela ezikhethelwe ukunyamezela kwimekobume yokubumba irabha. Ulwakhiwo olunzima, iinkqubo eziphezulu zolawulo lobushushu, kunye neendawo zenkonzo ezifikelelekayo ayibobunewunewu; zizinto eziyimfuneko ekugcineni ukuchaneka okufunwa ngamandla eRubber Molding kunye neRubber Material Testing protocols unyaka nonyaka. Oku kuthembeka okungayekiyo kuguqulela ngokuthe ngqo kwimveliso ezinzileyo, enokuxelwa kwangaphambili ehlangabezana neemfuno zangexesha nje zemarike yamacandelo erabha yemoto.

Kutheni "uomatshini boShicilelo lweRabha yeSiqinisekiso se-CE" ayisoSincamathelisi nje (kwaye kutheni i-Excels yam)

Isiqinisekiso se-CE soomatshini bokushicilela zerabha sisisiseko esiyimfuneko esisemthethweni kwimarike ye-EU, nto leyo ebonisa ukuthotyelwa kwezempilo, ukhuseleko, kunye nezikhokelo zokhuselo lokusingqongileyo. Kodwa ukugqwesa kokwenyani kudlulela ngaphaya kokuthobela nje kuphela. Oomatshini bam baquka umoya we-CE ngoku:

Ukhuseleko lweNdawo ngoYilo: Ngaphandle kokugada, cinga iisekethe ze-hydraulic ezingaphumeleliyo, ukukhuselwa kwe-thermal overload edityanisiweyo kwinqanaba lenkqubo, kunye neenkqubo zokunceda uxinzelelo eziyilwe ngokuphinda-phinda. Ukhuseleko alufakwanga bhotshi; Yenziwe ngobunjineli. Oku kukhusela abasebenzi bakho kwaye kuqinisekise imveliso engaphazanyiswa.

UkuSebenza kwamandla oKwakhelwe ngaphakathi: i-CE ityhala ukusebenza kakuhle; oomatshini bam bayayikhokela. Iinkqubo ezihlaziyiweyo ze-hydraulic (apho kufanelekileyo), ii-motor ze-servo eziphezulu, kunye nolawulo oluhlakaniphile lwe-thermal lunciphisa kakhulu iindleko zokusebenza xa kuthelekiswa nabadala, abakhuphisana be-guzzling yamandla. Oku asikokuhlamba nje uhlaza; lulutho olubalulekileyo lokhuphiswano kwimarike yanamhlanje.

Udibaniso loLawulo lokuKhusela: Iyilwe ngoonxibelelwano olukhethwayo lokutsalwa komsi kunye nokuhambelana neenkqubo zokupholisa ezivaliweyo, ukwenza ukuthotyelwa kwemithetho engqongqo yokusingqongileyo kube lula.

Umda woKhuphiswano: UkwiZiphumo

Xa ukhetha umatshini wam wokubumba inaliti yerabha, awuthengi nje isinyithi kunye ne-hydraulics. Utyala imali kwinkqubo eyilwe ukusuka phantsi ukuya phezulu ukuze ibe yeyona nto iphambili yokuqinisekisa umgangatho. Uyathenga:

Ukungangqinelani okungahambelaniyo: Nciphisa i-scrap, nciphisa ukusebenza kwakhona, uphumelele uphicotho ngaphandle komgudu. Betha i-tensile yakho, iseti yoxinzelelo, ubulukhuni, kunye nayo yonke enye into, ngalo lonke ixesha.

Ukugcinwa kwezinto eziphathekayo: Ukulawulwa kokudubula okuchanekileyo kunye ne-scrap encinci (enkosi kulawulo oluphezulu kunye ne-vacuum yokuzikhethela) kuphucula ngokuthe ngqo umgca wakho ophantsi. Iplastiki esebenzayo inciphisa imbali yobushushu obudibeneyo, igcina izinto eziphathekayo.

Isantya sokuya kwiMarike: Ukuthembeka kunye nokungaguquguquki kuthetha i-hiccups encinci yemveliso kunye nesiqinisekiso esikhawulezayo sezixhobo ezitsha kunye nemathiriyeli yokufuna izicelo ezinje ngenaliti yokubumba iiprojekthi zoshishino lweemoto.

Ubungqina bexesha elizayo: Yenzelwe ukuguquguquka - phatha yonke into ukusuka kwiikhompawundi ze-FKM ezifunwayo ze-aerospace ukuya kwi-silicone yodidi lwezonyango olubuthathaka (ukusebenza komatshini wokubumba inaliti yerabha ye-silicone yinto ekhethekileyo), ukuya kwi-EPDM ephezulu yemoto. Ukulungele ukuhlanganiswa okuzenzekelayo.

Uxolo lwengqondo: Ixhaswa bubuchule obunzulu boshishino kunye nenkxaso esekelwe kwi-30 + iminyaka, kungekhona nje incwadi yokuthengisa. Siyaziqonda iimvavanyo ojongene nazo kuba siyila oomatshini bokukunceda ukuba uphumelele.

Eyona nto ibalulekileyo: Musa ukungcakaza isidima sakho kwisiXhobo esiNgaphantsi

Kwihlabathi elikwinqanaba eliphezulu lokubumba irabha, ingakumbi ukubonelela ngeyona ndawo ibunjiweyo yerabha yemoto okanye ukuvelisa iimveliso zokungunda zocingo lwerabha ezibaluleke kakhulu, ukusebenza kovavanyo olungaguqukiyo akukhethi; yinto ekhoyo. Unokuba neyona khompawundi igqwesileyo kunye noyilo lokungunda, kodwa ukuba umatshini wakho wazisa ukuguquguquka, ukungazinzi, okanye ukungangqinelani, uya kusilela. Uya kujongana nokwaliwa okuxabisa imali eninzi. Uya kuphulukana nezivumelwano.

Oomatshini bam basekupheleni kweminyaka engamashumi amathathu yokuphulaphula, ukufunda, kunye nezisombululo zobunjineli kwiingxaki zangempela ezijongene nomgangatho wemveliso kunye nelebhu yokuvavanya. Zakhelwe ukuba ngawona maqabane athembekileyo, achanekileyo, kwaye angaguquguqukiyo kukufuna kwakho iindawo zerabha ezingenasiphako. Ayikokuthengisa ubaxo; sisiphumo esibonakalayo sefilosofi yomatshini emiliselwe kwinzululwazi esisiseko yeRubber Molding kunye neRubber Material Testing.

Ngoko, xa ubuza, "Kutheni i-RABBER INJECTION MACHINE yam ingcono kuneyakho?" Impendulo ilula: Kuba eyam yenzelwe ukuqinisekisa ukuba iindawo zakho ziyaluphumelela uvavanyo. Lonke uvavanyo. Ngalo lonke ixesha. Ngaba asiyiyo eyona nto ibalulekileyo leyo? Makhe sithethe malunga nokuba umatshini wam unokuba sisiseko sebali lakho lempumelelo esemgangathweni.

Ixesha lokuposa: Aug-22-2025